AI Scheduling for Manufacturing: Boost Shifts Fast

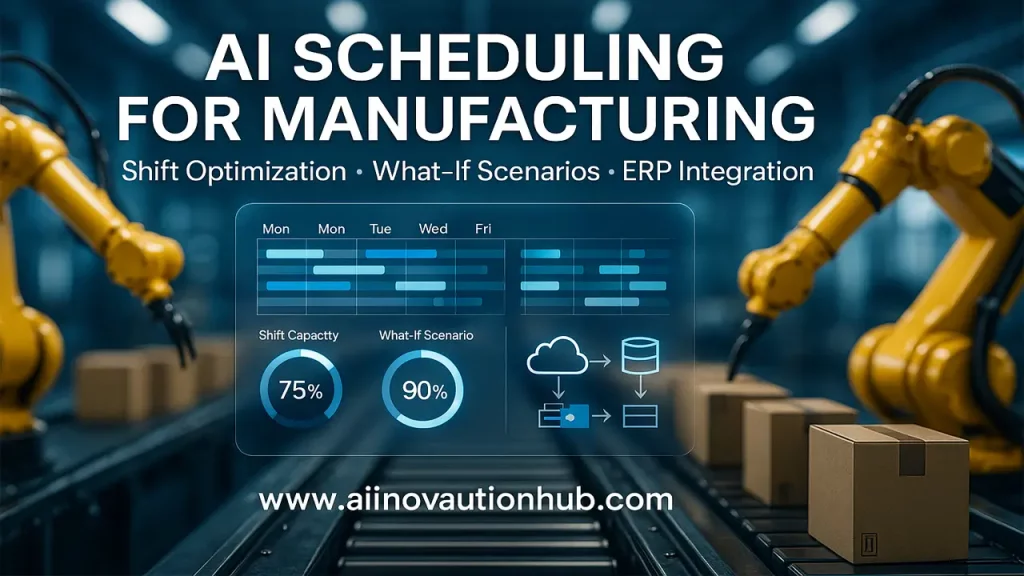

The manufacturing landscape is on the brink of a transformation, and at the heart of this change lies the innovative use of AI scheduling for manufacturing. This technology is not just a buzzword; it’s a game-changer that optimizes shift rotations, reduces downtime, and boosts productivity in ways that traditional methods can’t match. With AI workforce scheduling, manufacturers can predict staffing needs with greater accuracy, ensuring that labor is always efficiently distributed on the production line. Moreover, predictive scheduling software and production line scheduling AI enable real-time adjustments, minimizing idle time and maximizing factory throughput. To stay ahead of the curve and discover how AI scheduling for manufacturing can revolutionize your operations, subscribe to the website today.

Ready to take the next step? Then look at our house – https://aiinovationhub.com/

. Here we collect everything that helps the production and warehouse to work faster: AI-schedules, ERP integration, “what-if” scenarios, real cases and checklists for implementation without pain. We explain the complex simple language, like on YouTube, but without the ads in the screen. Do you want to choose a software? There are comparative tables and neutral reviews. Need ideas for quick win? Take ready-made process templates and KPI’s. Have you got a startup?

You will find tools for monetization, marketing and automation. Sign up for updates to catch weekly short digests and hidden tool chips. If you have any questions, send us an email and we will tell you where to save time, how to increase capacity and how to connect everything with the current stack. Welcome to the AI Innovation Hub – your AI application navigator. Start with a short implementation checklist, compare APS systems and case kits from FMCG, metalworking and 3PL – all in one place, without water. Save the link and share it with your colleagues.

Revolutionizing manufacturing with AI scheduling

By revolutionizing manufacturing with AI scheduling, companies are not only optimizing their production lines but also setting the stage for a smarter, more efficient industry. Traditional scheduling methods often rely on manual processes, which can lead to inefficiencies, errors, and increased downtime. However, with the advent of AI workforce scheduling, these challenges are being addressed in a way that was previously unimaginable.

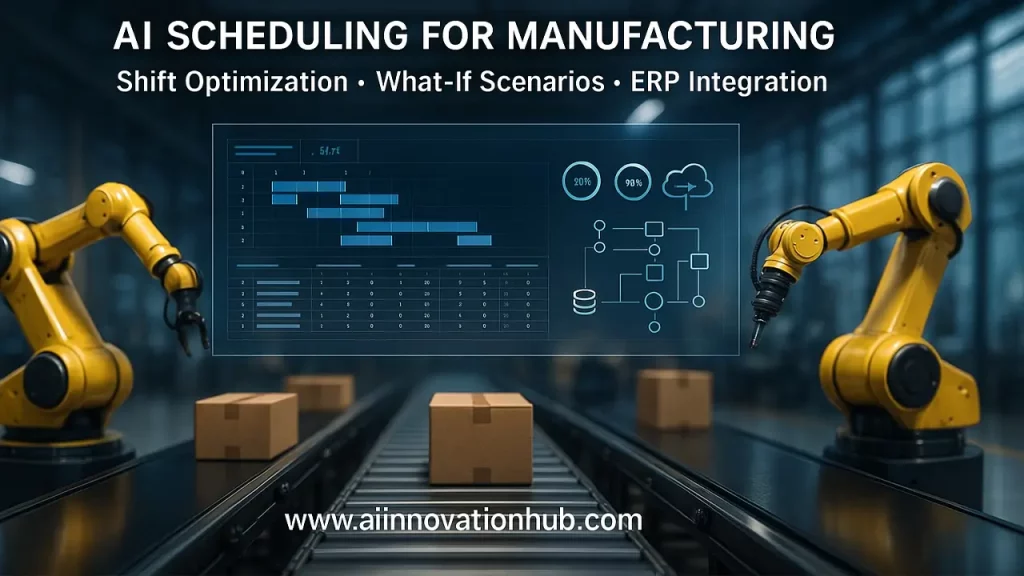

One of the most significant benefits of AI scheduling is its ability to optimize shift rotations. By analyzing historical data, current production demands, and even external factors like weather and economic trends, AI algorithms can create schedules that minimize downtime and maximize productivity. This level of manufacturing shift optimization ensures that the right number of workers are always in the right place at the right time, leading to smoother operations and fewer bottlenecks. For instance, AI can predict when certain machines are likely to require maintenance and adjust shifts accordingly, preventing unexpected breakdowns that can halt production.

Moreover, AI scheduling systems offer real-time adjustments, which are crucial in a dynamic manufacturing environment. These systems can quickly adapt to changes in production orders, material availability, and workforce attendance, ensuring that labor is distributed efficiently across the production lines. This real-time capability not only enhances productivity but also improves worker satisfaction by reducing the likelihood of overstaffing or understaffing. As a result, companies can respond more agilely to market demands and maintain a competitive edge.

A notable example of the impact of AI scheduling is a case study from a leading automotive manufacturer. By integrating AI scheduling with their existing ERP system for scheduling, the company was able to significantly improve inventory and production coordination. This integration allowed for better visibility into the entire production process, from raw material procurement to finished goods. As a result, the manufacturer reduced lead times, minimized inventory costs, and improved overall operational efficiency. The seamless integration of AI with ERP systems demonstrates the potential for comprehensive optimization across multiple facets of the manufacturing process.

In addition to these immediate benefits, advanced planning and scheduling AI (APS AI) is playing a crucial role in enhancing factory capacity planning. APS AI systems can simulate various production scenarios and provide actionable insights to help managers make informed decisions. This predictive capability is particularly valuable in industries with high variability in demand, where accurate capacity planning can mean the difference between meeting customer expectations and falling short. By leveraging APS AI, manufacturers can better anticipate future needs, allocate resources more effectively, and ultimately achieve higher levels of productivity and profitability.

Want to see where AI breaks down traditional supply chains and business models? Check out our guide «AI Industry Disruptions»: trends, cases, metrics, how to prepare the plant and warehouse for the next wave of automation. Useful checklists and ROI examples inside. Read: https://aiinovationhub.com/ai-industry-disruptions-aiinnovationhub-com/

Learn how to change shift schedules, capacity planning and ERP integration to win over competitors.

How AI shift scheduling software enhances productivity

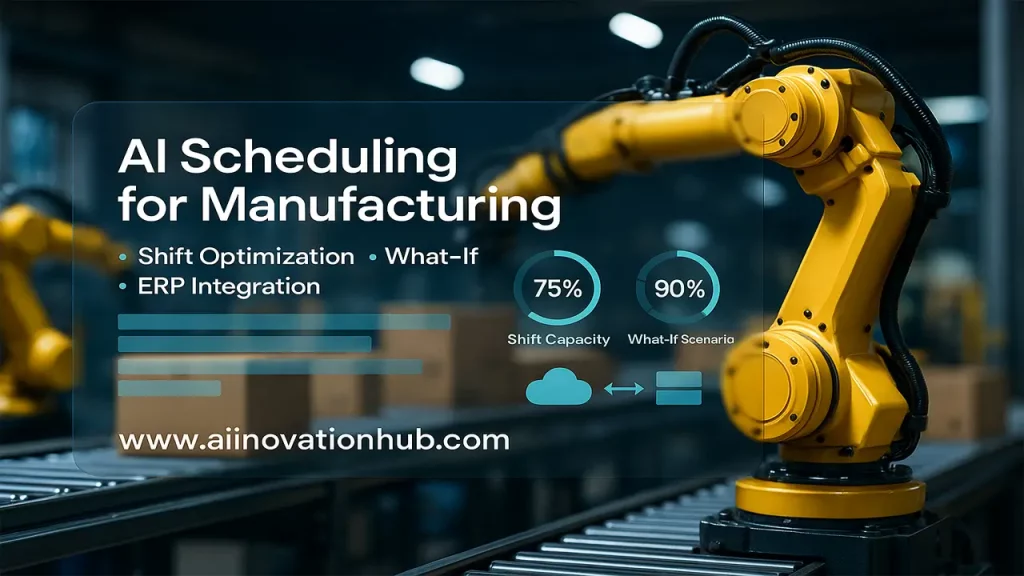

Discover how AI shift scheduling software can be the secret weapon in enhancing productivity, cutting through the complexities of workforce management with unprecedented accuracy. One of the most significant benefits of this technology is its ability to predict optimal shift lengths. By analyzing historical data, current production demands, and workforce availability, AI can determine the ideal duration for each shift, thereby reducing overtime costs and increasing output. This predictive capability ensures that the workforce is always aligned with the production schedule, leading to smoother operations and higher efficiency.

Moreover, AI shift scheduling software automates the process of what-if scenario planning in manufacturing. This means that managers can quickly explore various scheduling scenarios to find the most efficient labor allocation. For instance, if there is a sudden surge in demand or an unexpected equipment breakdown, the software can simulate different shift patterns and resource allocations to minimize disruptions. This real-time flexibility allows for better decision-making and ensures that the factory can adapt swiftly to changing conditions, ultimately enhancing productivity.

Seamless integration with ERP systems is another critical feature of AI shift scheduling software. By connecting with existing enterprise resource planning systems, the software can access a wealth of data, from inventory levels to production schedules, to make informed scheduling decisions. This integration not only streamlines the scheduling process but also ensures that all departments are working in harmony. For example, the software can automatically adjust shift schedules based on material availability, ensuring that production lines are never idle due to a lack of resources.

Real-time adjustments by AI shift scheduling software further minimize downtime and enhance overall factory throughput. The software continuously monitors production metrics and can make immediate changes to shift schedules to address bottlenecks or optimize resource utilization. This proactive approach helps maintain a steady production flow, reducing the likelihood of delays and ensuring that the factory operates at its maximum capacity. Additionally, advanced planning and scheduling AI can optimize warehouse tasks, improving material flow and reducing the time spent on manual coordination. By automating these tasks, the software ensures that materials are always where they need to be, just when they are needed, further boosting productivity.

If you are interested in smart manufacturing solutions, check out our autoproject – review of Chinese electric cars, tests, prices and comparisons. Like the format «without water»: facts, photos, real pros-cons. Start with collections of best EVs and hybrids 2025. Link: https://autochina.blog/

- save and share with colleagues. Current market news, buyer’s guide and honest expert recommendations.

Case studies: AI in action on the factory floor

From small-scale operations to large industrial complexes, the impact of AI scheduling for manufacturing is palpable—explore real-world case studies that highlight its effectiveness. In a leading automotive plant, the introduction of AI scheduling for manufacturing software has been a game-changer. Before the implementation, the plant faced significant challenges with downtime and inefficient shift scheduling. The AI system analyzed historical data, identified patterns, and optimized shift schedules to minimize idle time and maximize resource utilization.

As a result, the plant saw a notable reduction in downtime, leading to a more consistent and productive output. The software also ensured that the right number of workers were scheduled at the right times, which not only improved efficiency but also enhanced employee satisfaction by reducing overstaffing and understaffing issues.

In another instance, a warehouse leveraged warehouse labor optimization AI to transform its operations. The warehouse was struggling with order fulfillment delays and low staff morale due to manual scheduling processes that often led to mismatches between workforce availability and demand. By implementing AI workforce scheduling software, the warehouse was able to predict labor needs more accurately and schedule staff more effectively. This not only improved order fulfillment times but also led to a significant boost in staff morale, as employees felt more valued and better supported in their roles. The AI system’s ability to handle complex scheduling scenarios and provide real-time adjustments was a key factor in its success.

Production line scheduling AI has also proven to be a powerful tool in streamlining manufacturing operations. A factory that specializes in consumer electronics faced challenges with frequent production line stoppages and inefficiencies in material flow. By integrating production line scheduling AI, the factory was able to create more flexible and responsive schedules. The AI system monitored production in real-time, allowing for immediate adjustments to be made based on current conditions. This real-time capability not only reduced bottlenecks but also increased overall throughput, making the factory more competitive in a fast-paced market.

Factory capacity planning AI has further enhanced the robustness of production schedules. A large manufacturing facility used factory capacity planning AI to conduct what-if scenario planning, which helped them prepare for various production scenarios and potential disruptions. The AI system allowed the facility to simulate different production schedules and identify the most efficient and resilient options. This proactive approach ensured that the facility could maintain high levels of production even in the face of unforeseen challenges, such as supply chain disruptions or equipment failures.

Finally, the integration of ERP integration for scheduling has had a profound impact on administrative processes. A manufacturing company that previously relied on manual scheduling and data entry found that ERP integration for scheduling significantly reduced the administrative overhead. By automating the scheduling process and integrating it with their existing ERP system, the company was able to streamline data flow, reduce errors, and free up valuable time for their management team to focus on strategic initiatives. This integration not only improved operational efficiency but also enhanced the overall accuracy and reliability of the scheduling process.

Integrating AI scheduling with ERP systems

The seamless integration of AI scheduling with ERP systems is more than just a technological upgrade; it’s a strategic move that aligns all aspects of manufacturing for maximum efficiency. By connecting these two powerful tools, manufacturers can ensure that their workforce management and production planning are in perfect harmony. This integration allows AI to access real-time data from the ERP system, such as material availability and order changes, enabling it to make immediate and informed adjustments to shift schedules. This not only ensures that the right number of workers are available at the right times but also helps in minimizing downtime and maximizing productivity.

For instance, when an unexpected order surge occurs, ERP integration for scheduling ensures that the AI scheduling system can quickly pull the necessary data to adjust shift lengths and staffing levels. This real-time responsiveness is crucial in a fast-paced manufacturing environment where delays can have significant financial implications. Similarly, if there is a shortage of raw materials, the AI can reschedule shifts to avoid idle time and reallocate resources more effectively. This dynamic approach to scheduling helps in maintaining a smooth production flow and reduces the need for last-minute manual interventions.

Moreover, predictive scheduling software plays a pivotal role in optimizing labor for manufacturing demands. By analyzing historical data and current trends, the software can forecast future needs and proactively adjust schedules to prevent overstaffing or understaffing. This predictive capability not only reduces overtime costs but also ensures that the workforce is always aligned with production goals. For example, a manufacturer might use predictive scheduling to anticipate a rise in demand during a particular season and prepare accordingly, thereby avoiding the rush and potential bottlenecks.

In addition to predictive scheduling, the integration of AI with ERP systems enhances what-if scenario planning in manufacturing. Manufacturers can simulate various production scenarios and see how different scheduling changes would impact their operations. This allows them to quickly adapt to unexpected issues, such as machine breakdowns or supply chain disruptions, by running simulations and making informed decisions. For instance, if a critical piece of machinery goes down, the AI can quickly reassign tasks and adjust shifts to minimize the impact on production timelines.

Finally, the combination of advanced planning and scheduling AI (APS AI) within ERP systems significantly improves factory capacity utilization and efficiency. APS AI can analyze complex data sets to identify the most efficient ways to use available resources, including labor, machinery, and materials. This leads to better load balancing, reduced waste, and increased throughput. By leveraging the data from ERP systems, APS AI can provide insights that human planners might miss, ensuring that the factory operates at its optimal capacity at all times.

Future trends: AI and advanced planning in manufacturing

As we look to the future, the trends in AI and advanced planning are set to redefine the boundaries of what is possible in manufacturing, paving the way for a new era of innovation. One of the most significant advancements will be AI-driven predictive analytics. These sophisticated tools will not only anticipate demand more accurately but also reduce downtime and overstaffing, ensuring that resources are used more efficiently. By analyzing historical data, market trends, and real-time information, AI-driven predictive analytics will enable manufacturers to make informed decisions, leading to increased productivity and reduced operational costs.

Advanced planning and scheduling AI (APS AI) will play a pivotal role in optimizing production line scheduling. This technology will take into account a multitude of variables, from machine availability and maintenance schedules to material supply and workforce capacity, to create the most efficient production plans. APS AI will not only enhance the speed and accuracy of scheduling processes but also allow for dynamic adjustments in real-time, ensuring that any disruptions are quickly addressed and production continues smoothly.

Another transformative trend will be the ability of AI to enable what-if scenario planning in manufacturing. Manufacturers will be able to simulate various scenarios, such as equipment failures, supply chain disruptions, and sudden changes in demand, to better prepare for the unexpected. This capability will empower companies to develop robust contingency plans, minimizing the impact of unforeseen events and maintaining operational continuity. What-if scenario planning in manufacturing will also facilitate strategic decision-making, allowing leaders to explore different strategies and choose the most effective ones.

The integration of AI scheduling with ERP systems will further streamline operations and improve data accuracy. By connecting AI scheduling tools with existing ERP systems, manufacturers can ensure that all departments are working from the same, up-to-date information. This integration will eliminate data silos, reduce manual errors, and provide a unified view of the entire manufacturing process, from production to inventory management and beyond. The seamless flow of data will enable more informed and timely decisions, enhancing overall efficiency and responsiveness.

Lastly, warehouse labor optimization AI will revolutionize the way warehouses operate. This technology will dynamically adjust staffing levels based on real-time inventory levels and order volumes, ensuring that the warehouse is always optimally staffed. Warehouse labor optimization AI will not only reduce labor costs but also improve order fulfillment accuracy and speed, leading to higher customer satisfaction and operational excellence. As AI continues to evolve, its impact on every aspect of manufacturing will become increasingly profound, setting the stage for a future where technology and human ingenuity work hand in hand to achieve unprecedented levels of efficiency and innovation.